In this paper we present the design premise for the fourth LNG train and discuss how the basic “Two-Trains-in-One” concept was maintained whilst taking the capacity to the higher production level. The changes to layout, equipment, piping and instrumentation are addressed, as are the dynamics of the plant operating with such high throughputs.

What Does an LNG Train Look Like? What Does an Complete LNG Facility Look Like? Design of an LNG Plant. Typical inlet Composition? No, but an example: (nanograms) of mercury per cubic meter of gas. Therefore, why transport an undesirable component in the LNG?

or “train”. An LNG train performs three main processes: 1. Pretreatment. Dust and slug (water and condensate) is removed along with hydrogen sulfide (H. 2. S) and mercury (Hg). These pollutants can cause corrosion and freezing problems, especially in aluminum heat exchangers. 2. Acid Gas Removal and Dehydration . Carbon dioxide (CO. 2

Liquefied Natural Gas Process - an overview - ScienceDirect

The LNG process, consisting of liquefaction, transportation, storage, and regasification of LNG, is accompanied by certain energy demands. The paper focuses on the evaluation of the chain of energy transformations involved in the LNG process.

LNG and Liquefaction - Cameron LNG

An LNG Train performs four main processes: 1) Pretreatment. Remove dust and slug (water and condensate) along with hydrogen sulfide (H2S) and mercury (Hg). These pollutants can cause …

Schematic process flow diagram and simulated a LNG production …

In this research, a novel liquefied natural gas (LNG) reproduction process is developed to re-liquefy generated boil-off gas from the LNG tank through an ejector refrigeration unit driven by an...

Flowchart for LNG plant with two trains | Download Scientific Diagram

Download scientific diagram | Flowchart for LNG plant with two trains from publication: Natural gas transportation: NGH or LNG? | In this work, based on a process for conversion of natural...

LNG “trains” are designed for capacities up to 8 million tons per annum (MTPA) equivalent to about 1.2 Bcf/d. (Note: one metric ton of LNG contains 54.6 Mscf of gas, thus one MTPA contains 5.46 × 107Mscf/yr or 1.5 × 105Mscf/d or 0.15 Bcf/d.) An example of a LNG plant overall flow diagram and the main pro-cess units are shown in Figure 6–1.

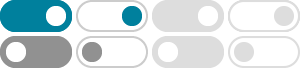

Typical Configurations of LNG Compression Trains.

Typical drive train configurations in oil and gas applications, such as LNG compression, are shown in Figure 1a-c. ... Torsional Mode Damping for Electrically Driven Gas Compression Trains in...

LNG produced in the U.S. is used for peak shaving purposes. Even for this function, LNG cannot distinguish itself from other mechanisms for natural gas storage, such as salt caverns. Secondly, domestic gas production, with the help of pipeline imports …

- 某些结果已被删除